1. The vessel has a steady temperature and even heating distribution inside

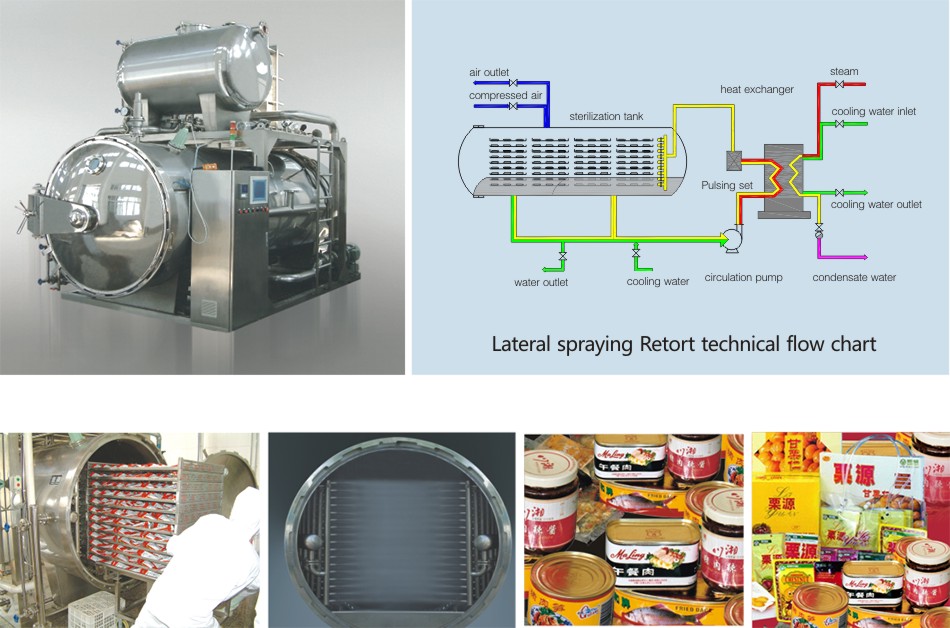

In order to get more uniform temperature and heat distribution. We equip both side of each tray with 3 fan-shaped nozzles inside the retort, and the nozzles spray the fan-shaped hot water uniformly, letting the material in every tray being heated uniformly. as well as keeping the inside temperature at an expected level during the sterilization processing, thus make sure the stability of value and lowest the possibility of over cooking.

2. quickly heating

Because there is a little circulating water inside, and the vessel adopts high efficient heat exchanger, So the temperature of food product will raise soon. Commonly, the water temperature will rise from 20℃to 121℃ in 10~15 minutes, preserving the food product's flavor and color as well as reducing the energy consumption.

3. Indirect heating and cooling prevents the second pollution

The circulating water will be heated or cooled through the plate type heat exchanger .Meantime, the water will be continuously cooled by the plate heat exchanger until the expected sterilization processing is done, effectively preventing the second pollution.

4. Applicable for different packages

During the whole sterilization, the sterilization mode can be divided into single period mode and multi period mode, meeting different sterilization requirement of different packages.

5. Complete pressure controlling, applicable for the sterilization of packages with gas inside Accurate pressure controlling, with anerror less than 0.005MPa. The inside temp-erature and pressure inside the tank will be inspected continuously, The controlling system will adjust the inside tank pressure in order to make it equal the pressure inside the packages. This equipment is applicable for the packages with or with-out gas inside, which is beneficial to prevent distortion and damages of containers.

6. controlling system

A. Siemens touching screen*

B. Paperless recorder*

C. The injection auto valve*

D. Analog temperature, pressure controlling system, sterilization temperature(±0.5℃), pressure(±0.005MPa)

E. There are various sterilization modes pre stored for choices , to a maximum of 260 sterilization formulas.

7. F value measuring function*

Each set of cooking vessel could be equipped with F value measuring function. Being treated by the data processing software, all the sterilization data, including sterilization condition, F value, time-temperature curve and time-pressure curve will be saved or printed, which offers convenience to production management.

Note:"*"means it is optional.

Note: We can equip and process the equipment according to the customers' requirements.

Note: We can equip and process the equipment according to the customers' requirements.

Contact support personnel

Wechant

Wechant